Saturday, November 3, 2007

ECO-friendly alternative to SALT softeners?

Tuesday, September 25, 2007

How do you determine if you actually need a softener?

How do you put a softener out of service without damaging it?

And unplug electric. If it the tank is in an area that could Freeze, move Tank to area that Can't Freeze.

* When you are ready to use the softener again, besides turning the water back on, restoring electric to control, and setting time of day, you will want to manually start a regeneration of the system to "freshen" up the water in the Tank, before using the water in the home.

Monday, August 6, 2007

No Salt Systems for Water Softening

I see ads for "No Salt" needed water

conditioners.

How do they work without using salt?

1. Many dealers will advertise a no salt water conditioner. Any brand of water conditioner can be operated without using salt. This is done by using a salt substitute, potassium chloride. It generally cost twice as much as regular salt ( sodium chloride ), and can be difficult to find in some areas. Also, it is recommend to increase the salt setting on your control valve by about 10 % , when using a salt substitute. This is because it is not as efficient in provided the needed negative ions to the resin beads as regular salt.

2. Some companies offer catalytic filters and/or magnetic devices to soften your water that do not use salt, or anything else to regenerate their product. Buyer beware! If a technology had been developed that could replace a resin based water conditioner, then everyone would be selling it. I know I would. Those salt bags are heavy :)

Salt is Not Going Down

My Valve appears to be operating but the Salt is Not Going Down.

What could cause this problem?

The salt not going down could be due to many different reasons.

1 ) Valve is not regenerating due to a problem with Timer Motor or a bad gear in the timer assembly ( common in Autotrol Timer Assemblies ).

2 ) Salt may be Bridged ( become solid ) above water that is at the bottom of the salt tank.

3 ) If you have been using Pellet salt for many years you could have a lot of undissolvable residue at the bottom. This residue will not dissolve and also can block water flow in and out of the salt tank.

4 ) The Valve could be failing to draw the brine solution out and if you have a float shut off in the brine tank, it would be prevent the salt tank from overflowing ( which it would do if the float shut off was not there ).

5 ) The brine refill control could be clogged, prevent water to refill the salt tank.

Sunday, July 22, 2007

How to use Autotrol By Pass - Old Style

Wednesday, July 18, 2007

Rainsoft Amazon Gold Series Seals ( Gaskets ) and Spacers are Fleck Parts

The Seals are pn 13242 ( quantity 5 ) and the Spacers are pn 14241 ( quantity 4 ) , and the end spacer is pn 18264 ( and this part can normally be re-used, that is why the 60125 Kit will also work as a replacement ).

Monday, July 16, 2007

Tank Diameter - How to Measure and Why It Matters

* Yes, you measure the fiberglass tank that contains the resins ( or other

media ).

Do not be "fooled" by plastic decorative "jackets" sometimes placed over the

fiberglass ( or polyglass ) tank.

The diameter is the measurement ACROSS the WIDTH of the tank, or the

circumference ( around ) the tank divided by pi ( 3.14 ).

And you should "round down" to the whole number ( i.e. 8.34 would be 8

inches ).

Why do you need this measurement?

* The proper Backwash Flow Rate to be used is determined by the diameter of

the tank.

The larger the diameter, the higher the flow rate required to properly

expand and clean the resin bed.

If your current valve body is an "Autotrol" type, it has a "Backwash" Plug

( PN 25F ) that has a small

number ( and the words "Backwash" ) on it. This number normally corresponds

to

the diameter of the resin tank.

See:

Autotrol Backwash Plug Sizes

* Fleck valves use DLFC ( drain line flow control ) buttons. The gpm is

sometimes marked near the drain fitting outlet.

See:

Common 2 gpm DLFC Button PN 12087

* Also, the injector size used in the Valve is determined by the diameter

of the resin

tank.

Autotrol valve examples,

See:

Common Autotrol Injector Sizes / Colors PN AP28F

And for Fleck Valves,

See:

Common Fleck Injector Sizes / Colors

All these are DIRECTLY based in the Tank Diameter, because the wider the tank, the higher the flow rates need to be for proper washing and rinsing of the media in the tank.

Monday, July 2, 2007

Clearing Memory in Sears, GE, and NorthStar Circuit Board

control will "remember" this for a long time.

In the case of the controllers commonly used in Sears, GE, and NorthStar

this could be 3 or 4 months before things would return to normal.

The problem caused by this "memory" is that the unit will be regenerating

more often than normal, because it is remembering the high usage, and

averages this into it's calculations of capacity remaining.

It "errs" on the side of caution, and ends up regenerating sooner than it

"really" needs to.

To reset this memory:

1 ) Hold "Select" button for 3 seconds, until 000 appears, then release.

2 ) Hold UP Arrow to "see" days the system has been plugged into the

electric, and release.

3 ) Hold DOWN Arrow to "see" number of times the system has regenerated

since it was first installed, and release.

NOW

4 ) Hold "Select" button for another 3 seconds to see the SR, or Model

code.

Write this number down.

5 ) Having released the "Select" button, and recording your actual model

code, then you can use the UP or DOWN Arrow to change your Model Code.

6 ) Press "Select" one time and you will see the time of day flashing 12:00

a.m.

7 ) Use the Arrow keys to move the time a few minutes, thus causing it to

"set" this new time.

FINALLY

8 ) Go back and do 1 - 7 again, only this time, at step 5, reset the

original model code, and at step 7, put in the correct time of day.

* NOTE: The number of regenerations since unit installed will be reset to

Zero. If you want to have this information for future referrence, be sure

to

write this down.

Wednesday, June 20, 2007

How Long Until Water Feels Soft Again After Repair

Saturday, June 16, 2007

Does Softenerparts.com ship to Canada

We ship to Canada all the time.

Small parts under 16 ounces can be shipped by Air Mail in large bubbled envelope ( and pass through Canadian Customs with little or no delay ).

Parts usually arrive in about one week.

Items weighing up to 4 lbs. and under $ 400.00 can also be shipped using standard Air Mail ( cost based on weight items and calculated in your CART once you input your ADDRESS ), BUT large items that require a box, can take 2 - 6 weeks to arrive ( as some are "selected" by Canadian Customs, and that can slow delivery time ), and is therefore not recommended for items over 1 lb. if you can't wait that long.

Items up to 10 lbs. can be shipped by Express Mail ( Costs start around $ 32.00 and are based on weight, with calculation occurring in your CART once you've entered your Ship to: ADDRESS ) which is normally 5 - 7 business days delivery and includes Tracking Number.

Please try adding your items to the Shopping Cart, enter your address for a "shipping quote".

Orders can and should be placed online. Shipping will be quoted based in the weight of the items.

Express Mail shipping upgrade is available during check out. The shopping cart will quote any order weighing less then 10 lbs. and offer a minimum quote for heavier orders.

We will contact you if any additional shipping charges are required for heavier items ( over 10 lbs. ).

Also see, Shipping Questions: When, How Long, From Where, What Methods.

ANY TAX or DUTY will be paid by YOU when order is delivered, we do NOT collect this in advance.

3.2.1 Customs Duties and Taxes

Canadian Customs Requirements

Customs Duties, Taxes and Exemptions

3.2.1

Any item mailed into Canada is potentially subject to duty and/or taxes with few exceptions.

Visit the CBSA web site at www.cbsa-asfc.gc.ca/security-securite/cbcr-dmte/menu-eng.html for more information on mail imports. The CBSA collects provincial sales taxes (PST) on most taxable imports valued at over $20CDN entering Quebec, Ontario, Manitoba, Saskatchewan and British Columbia. The CBSA also collects Harmonized Sales Taxes (HST) on most taxable imports entering Newfoundland and Labrador, Nova Scotia and New Brunswick.

We do not use UPS for shipments to Canada, as the "broker" fees can be more than the cost of the item.

Also, UPS requires higher costs and paper work to ship International...

So we just don't use them.

Only the Postal Service is used to ship to Canada.

Sunday, June 10, 2007

Bruner Valve - Old and New Styles

Friday, June 8, 2007

Too much Sodium in the Water?

Only if a person is on an extremely restrictive diet, he should drink neither hard nor softened water. Under these conditions, he should use reverse osmosis, or distilled water for drinking and cooking. For a normal person, the small amount of sodium in water is not a problem or concern. Especially when compared to other foods.

Even hard water may contain appreciable amounts of sodium. To determine the amount a complete analysis of the water is necessary.

It is important to note that about 2/3 of the daily water intake of the individual is through food and only about 1/3 water itself.

| SODIUM CONTENT OF COMMON FOODS IN A TYPICAL DAILY DIET | ||

| The Food | Amount | Milligrams of Sodium |

| Milk | 2 cups | 226 |

| Eggs | 1 of medium size | 56 |

| Steak | 6 ounces | 110 |

| Bread | 2 slices | 278 |

| Cereal | 1/2 cup | 21 |

| Potatoes | 1 small | 30 |

| Green salad with 1 oz French Dressing | 1 serving | 30 |

| Vegetables (other) | 3 servings | 120 |

| Fruit | 2 servings | 50 |

| Fruit (citrus) | 1 serving | 6 |

| Water after typical water softener | 8 ounces | 25 average |

Monday, June 4, 2007

Autotrol 440 Timer Rebuilding

Sunday, June 3, 2007

Salty Water Taste in the Morning

Sunday, May 27, 2007

Trouble Shooting Fleck 9000 Valve

Checking the Meter Operation is the first step.

See:

Meter Cover ( 14038 ) and how to Check Directions plus Video

If the meter is counting your water usage, it should be regenerating and

alternating tanks on a regular basis.

If the meter is counting down to zero, but the valve is not regenerating, it

could be one of several things.

1 ) Micro-switch that "starts" the timer motor, or the timer motor does not

start at all. Replacing the micro-switch or the motor would solve this.

You can "see" the timer motor running in the back of the motor, when it has

been "started" by the tripping of the micro-switch.

This is what the program wheel on the front normally does ( when it counts

down to zero ), or when you manually advance the control knob on the front.

2 ) The Drive Motor may be bad, and not turning the main ( middle gear ) to

move the Piston assemblies

3 ) The one or more of the drive gears may be broken.

4 ) The Valve could be "stuck" because the 2 main pistons, and seals need to

be replaced. A stuck valve can also damage the middle drive gear.

See:

9000 or 9100 Rebuild Kit Pistons and Seals

Diagrams of the Fleck 9000 Valve and a list of common replacement parts can

be found here,

See:

9000,9100 Parts and Diagrams

Wednesday, May 16, 2007

Distributor Failure in Bottom of Resin Tank

This time he thinks he may have lost the majority of his resin.

Can you please shed some light on possible causes for distributors to fail.

I'd like to make sure his third one lasts longer.

* Here is what I know will effect distributor life.

1 ) Too much water pressure ( over 80 psi ).

2 ) Not backwashing ( regenerating ) often enough. System should regenerate

at least once every 7 days.

I've run into "metered" or "demand" systems with just one or two people and

it takes them 2 - 3 weeks to "require" a regeneration.

This is too long for the resins to be "packed" down and not "fluffed up".

3 ) Highly Chlorinated water can break the resins down into small fragments.

These fragments get stuck in the fine slots of the bottom distributor. This

results in there being less "holes" for the water to flow through, thus

causing the pressure through the remaining holes or slots to become very

high. Eventually the pressure of the water becomes too high and the plastic

gives way. Then the larger ( normal size ) resins can get into the pipes.

4 ) Too high of flow rates can be a problem. Residential size softeners (

tank diameters between 8 - 10 inches ) are made for flow rates of less than

8 gpm. And a normal home will peak around 5 - 6 gpm while filling the

laundry tub, or the bath tub. If the demand it greater than this, the system

needs to have a larger tank diameter, and a gravel under bedding should be

used.

Tuesday, May 15, 2007

RESET Autotrol 460 Timer Regenerating EVERY NIGHT

* 1. Record your Hardness and Capacity settings

* 2. Disconnect power

* 3. Jumper both pins 'A' and 'B'

* 4. Reconnect power for at least 10 seconds

* 5. Disconnect Power

* 6. Remove Jumpers and return them to 'time' and 'spare'

* 7. Reconnect power and restore your hardness and capacity settings

* Result is # days since regeneration and gallons used are '0'

* Average daily usage is hex 64 or decimal 100 gallons

The REASON you would RESET your timer is IF the unit is Regenerating EVERY NIGHT. This happens when the "program" is "averaging" your daily use based on the last 30 days, and you had an unusually HIGH USAGE day during that period. A Reset should solve this problem. If not, it may be time to replace the Timer Assembly.

Friday, May 11, 2007

What Brine ( Salt ) Setting Amount to Use?

on the hardness of the water?

I haven't changed it from where it was set but didn't know if I needed too.

****

The amount of salt needed is mostly based on the amount of resins being

recharged.

3/4 cu.ft. resin = 6 - 9 lbs.

1 cu.ft. resin = 8 - 10 lbs.

1.5 cu.ft resin = 12 - 15 lbs.

Typically,

9 lbs for 8 - 9 inch tanks,

and 12 lbs. of 10" tanks is average.

If there is a lot of iron ( over 2 ppm )

or if the water is really hard ( over 25 grains ),

then 2 - 4 lbs. extra should be used.

So, typically a residential system will use 6 - 12 lbs of salt per regeneration at least once a week. Very hard water, or water high in iron, may require regenerating every 2 or 3 days. The result is you will be using at least 30 - 40 lbs. of salt, and more common you will be using 60 - 100 lbs. of salt per month. Simply multiply the pounds of salt per regeneration times the number of regenerations in a month to calculate your monthly average usage.

P.S. If you run out of Salt, don't expect to have soft water after a few days. And it may take more than one regeneration to get the water feeling soft again once you've added salt.

I recommend keeping the salt level above the water level in your Brine Tank.

When you start seeing the water level ( normally between 6 - 12 inches ) then it's time to think about adding more salt ( 40 - 120 lbs. ).

Replacing Program Wheel on Fleck 5600 Valve - Label comment

I appreciate the information on replacing the program wheel, but I would

suggest that you call the labels thin decorative covers on the front control

knob and program wheel not labels. They do not label anything.

Kay

Thursday, May 10, 2007

Replacing Program Wheel on Fleck 5600 Valve

http://softenerparts.zoovy.com/category/6600.fleck_5600_service_hints.checking_meter__setting

Brine Draw Failure in Sears, GE Smart Water, North Star Systems

1 ) Gasket under Nozzle Venturi is worn, cracked, or "dried out".

2 ) Seal Kit is failing at some critical area, and not sealing.

3 ) Rotor Disc is no longer smooth and even, resulting in lack of seal

during critical valve functions.

So, the best recommendation is to replace all 3 parts, unless you feel very

confident of the condition of one or more of the parts and there fore don't need replacing ( yet ).

See:

http://www.softenerparts.com/Seal_Kit_7129716_7092163_7134224_WS35X10005_p/7129716.htm

1 ) Gasket under Venturi ( sometimes the Venturi too ).

2 ) Seal Kit orings ( any leakage internally effects suction )

3 ) Rotor Disc ( any scratches or uneven wear effects suction )

4 ) Drain flow ( blockage of Drain Flow Plug or Drain hose effects suction... or Drain hose running UP HILL )

5 ) Bottom Flow Plug in the Nozzle Venturi Assembly, if closing up ( should be 0.3" I.D. hole )

6 ) Poor seal of the Nozzle Venturi Assembly to the Valve body ( oring pair 7170319 ).

*** And last but not least, if you have being using Pellet Salt for many years, it could be clogging the bottom of your brine well, and limiting flow at the bottom of the salt tank.

Pellet salt leaves a hard undissolvable mush of 1 - 3 inches per year of normal use. And eventually will clog the flow through the brine well at the bottom of the salt tank area.

Wednesday, May 9, 2007

Customers Asked Questions and Answers

Brine Refill after Autotrol 155 or 255 repair

I just order and received an output connector for an Autotrol timer. Great service!

I replaced the output connector last night and I am not sure that the brine actually was pulled out of the tank. I had to dispose of the

contents of the brine tank because it had a lot of dark particles in it. I assume this happened when the part broke and valves where opened out of sync.

So I replaced the salt and added about 4 gallons of water to the brine tank. I set the manual regeneration on and observed most of the cycle. When it got to the first brine cycle, I did not see any water being pulled from the brine tank. How do I know that brine is being pulled from the tank?

At one point the ball in the clear cup was pulled to the bottom of the cup but I did not see any water flow on top of it. Late in the cycle I did see brine water in the clear cup, with the ball at the top of the cup, and it appeared to be filling the brine tank.

How do I know the system is working correctly?

Thanks,

Greg L.

ANSWER:

Dear Greg,

The system should work the next time it regenerates. It did not work when you first did it because there would have been air in the brine line tubing from your cleaning of the brine tank. When ever you disconnect the brine tubing or anything that causes the water to come out of the air check or tubing, you MUST put the valve in brine refill for about 15 seconds ( after you have everything reconnected ) to purge any air from the air check and the tubing.

Your system "air checked" too soon because of the air in the tubing. But as I said, it should be okay NOW. You can see the water being pulled into the valve through the air check ( it takes 5 - 15 minutes to empty the brine tank ) and watch the water level drop in the brine tank, when the system is working correctly.

Autotrol 155 or 255 - How to Tell Which You Have

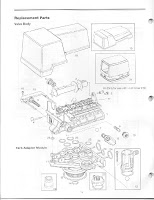

Above is the 155 Valve Body Diagram

Below is the newer 255 Valve Body Diagram

Click on to ENLARGE VIEW

How do I know if I have an Autotrol 155 ( 1550-TC ) or a model 255 Valve?

How do I know if I have an Autotrol 155 ( 1550-TC ) or a model 255 Valve?1. The Series 155 was replaced by the Series 255 late 1995 ( early 1996 ). An easy way to tell the difference is, the brine control ( salt dial ) is located on the front ( just beneath the timer housing ) on the 155 and it has been relocated to the right side ( looking from the front ) on the 255.

Another noticeable difference is the Injector Cap, and Injector Screen/Cap are the size of a quarter on the newer 255. They are about the size of a dime on the older model 155.

Note: The Brine Control and the Backwash Flow Control plugs are identical in size on both the 155 and the 255. However, another difference is the location of the Backwash Flow Control Plug ( 25F )is on the right hand side ( looking from the front ) on the 155 and has been moved to the left side on the 255.

Autotrol Backwash Plug Number

Can I replace just the control valve head and reuse my resin tank, and salt tank?

1. Yes. See < How to Replace Your Old Valve >

Will a Water Softener make the water safe to drink?

Will a Water Softener make my water safe to drink?

1. No. Your water must be safe to drink before you condition the water with a softener. If you are concerned about the safety of your drinking water, contact your local health department about getting a bacteria test, or full lab analysis on your water.

Common Water Problems

What types of water problems are common?

Hardness in your water.Hardness is dissolved rock and minerals like calcium and magnesium. Water hardness causes scale build-up in your pipes, washing machine, automatic dishwasher and hot water heater. Using hard water in your home can cost you up to 26% more in electrical bills, and up to 80% more in soaps and cleansing products. Not to mention the costly replacement of plumbing, water using appliances (ice makers), dishes and clothing. Try to bath or shower in hard water and it can leave your skin feeling dry and itchy, and your hair feeling dry and like straw.>

Iron and Rust in your water.

Iron and rust in your water is picked up from underground sources as rain water fitters down through the ground on its way to our aquifers. Iron and rust makes your water taste and smell metallic. It will stain your toilets rusty red, etch your china, corrode your washing machine and plug your pipes. it can ruin your hot water heater in less than a year, and will stain rusty red. Try and take a bath or shower and your skin feels dirty even after you have used tons of soap.

Tannic Acid in your water.

Tannic adds stain and discolor your water and cause it to look yellow and even green in some cases. Tannic acids are caused by decaying organic matter on the grounds surface that is leached into the ground aquifers via rain and runoff. Tannic acid in your water can stain clothing, appliances, and build up in your plumbing system over a short period of time.

Sulfur (Hydrogen Sulfide) in your water.

Hydrogen sulfide is a gas that causes an obnoxious rotten egg odor in your water. Hydrogen sulfide is caused by rotting and decaying organic matter in the underground aquifer. Hydrogen sulfide will ruin your silverware, plug your appliances, and generally stink up your whole house.

Chlorine in your water.

If your water comes from a public water supply, it probably has chlorine in it. The water utilities add chlorine to the water for disinfection purposes. Chlorine in your water can cause a swimming pool odor, and can be less than desirable to bath in, cook with, or drink. It is well documented that when you add chlorine to water containing organic matter (tannic add) it can form carcinogenic chemicals like Trihalomethanes. Some experts now believe that even the inhalation of these vapors may not be healthy. Public water supplies from surface water plants ( lakes, reservoirs ) can also contain deadly Cryptosporidium < Click for more information. Chlorine can also destroy the rubber components in a water softener ( and your plumbing ). Sodium Chloride (Salt) in your water.

Sodium chloride (salt) occurs naturally in our ground water and some water systems even add more. Salt is an essential element of life but most experts agree that we probably get more than enough in our diet and do not need more in our drinking and cooking water. if your on a salt free or salt restricted diet, you should not have any additional salt in your water.

Contamination in your water.

Contamination can be caused by many things. Some of the more common causes are improperly functioning septic tanks, leaking underground storage tanks, the use of fertilizers, the use of pesticides, animal waste, bacteria, virus, improperly disposed chemicals, organic and inorganic chemicals. The United States Environmental Protection Agency has established a list of both Primary and Secondary Drinking Water Standards and the WQA has a list of recognized treatment methods for meeting those standards.

Also see Common Water Problems

How a water softener actually works

How does my water softener actually work?

1. See Water Softener Basics

Why does soft water feel slimy or slick in the shower?

1. Water that has been conditioned by a water softener allows soap to dissolve more completely than in hard water. It is common for first time users of soft water to have a slimy experience in the shower. This is due to using more soap than is necessary. The amount of soap needed to lather up is very small in soft water. This is one of the benefits of soft water ( less soap is needed in the bathing, laundry, and household cleaning ). Also, the pores of your skin will no longer be clogged by the undissolved soap. Once a person has adjusted their soap usage and is used to the smooth clean feeling achieved by bathing in soft water, they will have a negative "ruff" feeling, if they bath in hard water again.

Odor in water

1. Water softeners do not remove most taste and odor problems ( they can remove the metallic taste of iron in water ).

2. Odors from hydrogen sulfide ( "rotten egg smell" ) in wells or "bleach" smell in chlorine treated water, require an activated carbon filter to be used in conjunction with the water softener. E-mail us for advice on your situation.

3. Sometimes odor in the hot water only, is caused by the self sacrificing rod installed in your hot water heater. Removal of this rod by your plumber could solve this problem.

Iron removal with water softener

Will a Water Softener remove the iron from my water?

1. Yes, if the iron is still in solution ( it has not been oxidized ). How much it can remove depends on the size resin tank of your softener. The more iron in the water, the larger the resin tank needs to be to remove all the iron. E-mail us for advice on your situation.

I have a working Water Softener, but I am still getting Iron Staining. Why is that?

There are several things that could cause you to still be getting staining.

1) It is critical that your system never run empty of salt.

2) It is important that the time of day be kept correct and that no one uses water between 2 a.m. - 3 a.m. when the system is regenerating. While the system is in regeneration, any water used would be unconditioned ( coming straight

from the well ).

3) In high iron situations it is usually necessary to include a cleaner with the salt. Iron Out ( about 1/4 cup with each 80 lbs of Salt ) is commonly used. So is Tan-X ( Citric Acid, also 1/4 lbs per 80 lbs. ). A cup or two of Chlorine Bleach

can be used, if your softener DOES NOT have "white resins" installed for Tannic Acid Color removal ( this is a special

layer of resins sometimes added to the regular resin inside your resin tank ).

4) It could be your resin tank is too small to handle all the iron.

A. What size is the resin tank?

B. What is the level of Iron and Hardness of the water?

5) It could be you are not regenerating often enough, or using enough salt per regeneration.

A. How often does your softener regenerate?

B. How many people are using the water?

C. How much salt are you using per month?

6) On rare occasions the iron could be coming from just the hot water tank. I've seen a few old ones ( over 20 years old ) rusting out on the inside, thus putting iron back into the water. This is also true in older mobile homes ( again over

20 years old ) that used galvanized plumbing under the trailer.

Above are the common reasons a working water softener might still be allowing you to get staining. For additional help and recommendations, please send the answers to the above questions.

Salt usage in water softener

How much salt should my softener be using?

1. The average is 80 lbs. per month, BUT can vary depending upon the type of valve used and the quality of water being treated.

2. Metered valves will tend to use less salt than a non metered unit ( i.e. one set to regenerate every so many days with no regards for actual water used ).

3. An average softener with 1 cu. ft. of resins ( 32,000 grain, 9" x 48" tank ) should use about 8 lbs. per regeneration to achieve a economical 24,000 grain capacity ( hardness in grains divided into grains of capacity results in the gallons of water that can be treated before resins is exhausted ).

I see ads for "No Salt" needed water

conditioners.

How do they work without using salt?

1. Many dealers will advertise a no salt water conditioner. Any brand of water conditioner can be operated without using salt. This is done by using a salt substitute, potassium chloride. It generally cost twice as much as regular salt ( sodium chloride ), and can be difficult to find in some areas. Also, it is recommend to increase the salt setting on your control valve by about 10 % , when using a salt substitute.

2. Some companies offer catalytic filters and/or magnetic devices to soften your water that do not use salt, or anything else to regenerate their product. Buyer beware! If a technology had been developed that could replace a resin based water conditioner, then everyone would be selling it. I know I would. Those salt bags are heavy :)

Low Pressure through softener resin tank

When do the resins in the softener tank need to be changed?

1. The average water softener will not need it's resins replaced in it's life time ( 20 + years ).

2. Water softening resins need to be replaced if the unit has developed a high level of bacteria that does not respond to a cleaning with chlorine. Odors from units left in a not working mode with no water flowing through them for months at a time can develop this problem. Also, units in direct sunlight ( Florida ) can develop a layer of algae that requires complete resin replacement.

3. An excessive amount of sand in resin tank, due to a well starting to collapse, can necessitate resin replacement.

For more Info:

Check out the Resin Replacement Guide

Can the softener cause pressure loss, if so what do I look for, and what do I need to fix it?

Yes, a softener can cause pressure loss in the home due to resistance from the resin bed caused by one of the following.

1. On well water, this is usually due to fine sand coming from the well.

2. On softeners installed in the open sunlight ( mostly in Florida ), a layer of algae can grow and thick pieces of this growth clog the lower distributor tube screen when they start peeling off the inside of the resin tank.

3. On chlorinated water supplies, sand can get into the tank from new construction or work on water lines in the area. All of these situations are rare.

4. The most common cause of pressure loss occurs on chlorinated water.

The resins can be damaged by high chlorine levels and turn to mush. This has the same effect as having fine sand at the bottom of the resin tank. Chlorine can DESTROY Resins in as little as 5 years ( I'm seeing 5 - 10 years average )

The solution for all of the above problems is to dump the resin tank, clean and rebed with new resins. One cubic foot of softening resins is enough to properly fill the average residential softener. We can calculate the amount for you, if you provide exact resin tank dimensions.

The second most common reason for pressure loss occurs with Autotrol control valves.

The flapper valve discs swell up when used on chlorinated water. This causes the holes in the valve to become block, resulting in pressure loss at high flow rates.

The solution for this problem is to replace the valve discs set and the backwash flow control ball ( this part also swells up ). See Autotrol Parts Page

Softener does not remove the water from salt tank when it regenerates. What should you check?

1. Make sure all the fittings are tight. Also check the tubing going to the salt tank for small cracks. Any air leak will cause the valve to not draw the water out during the regeneration cycle.

2. Make sure the drain line is not clogged or restricted. This also can cause the valves normal suction to fail.

3. Check the injector and injector screen for debris or clogging.

4. On Autotrol valves, check that the two large main valves ( # 2 and # 3 ) are fully closed during the Brine Rinse ( Draw ) cycle. If they fail to close, it results in no suction. In fact it will result in the valve attempting to fill the salt tank during the time it should be removing the salt water. This could be caused by something near the metal "tab" blocking the "tab" from standing straight up ( closing the rubber valve underneath, inside ), OR you could have something inside preventing full closure. On older valves, this can be caused by chlorine damage to the rubber valve discs. See the Rebuild guides on our Do It Yourself ( DIY ) Repairs page for more about the Valve Discs functions and how to replace them. For Piston Assembly or Rotor Disc Valves, the problem can be caused by internal leaks due to wear or damaged Pistons, Rotor, and especially the Seals they contact with in the control valve. Replacement guides for common types will be found on our DIY repairs page.

5. If your Resin Tank is INSIDE the Brine Tank ( one piece "cabinet" design popular in Europe and the U.S.A. ), you may have a leak in the RESIN TANK. Try unplugging the electric, so the Valve can NOT regenerate, and see if the water level continues to Rise from one day to the next.

6. Also check for leaking of the Brine Valve, which should be closed after the Brine Refill is completed. You can disconnect the Brine tubing at the Control Valve end to make sure the Valve is not sending any water to the Brine Tank area ( this could occur if the # 1 Valve Disc ( on Autotrol Valves ) or Brine Piston Assembly ( on Fleck Valves ) or Internal Seal leak ( on Rotor Disc type valves ) is being held open by debris of some kind or is very worn due to age.